Success or failure hinges on this one move: Intel's $32 billion gamble on 18A process

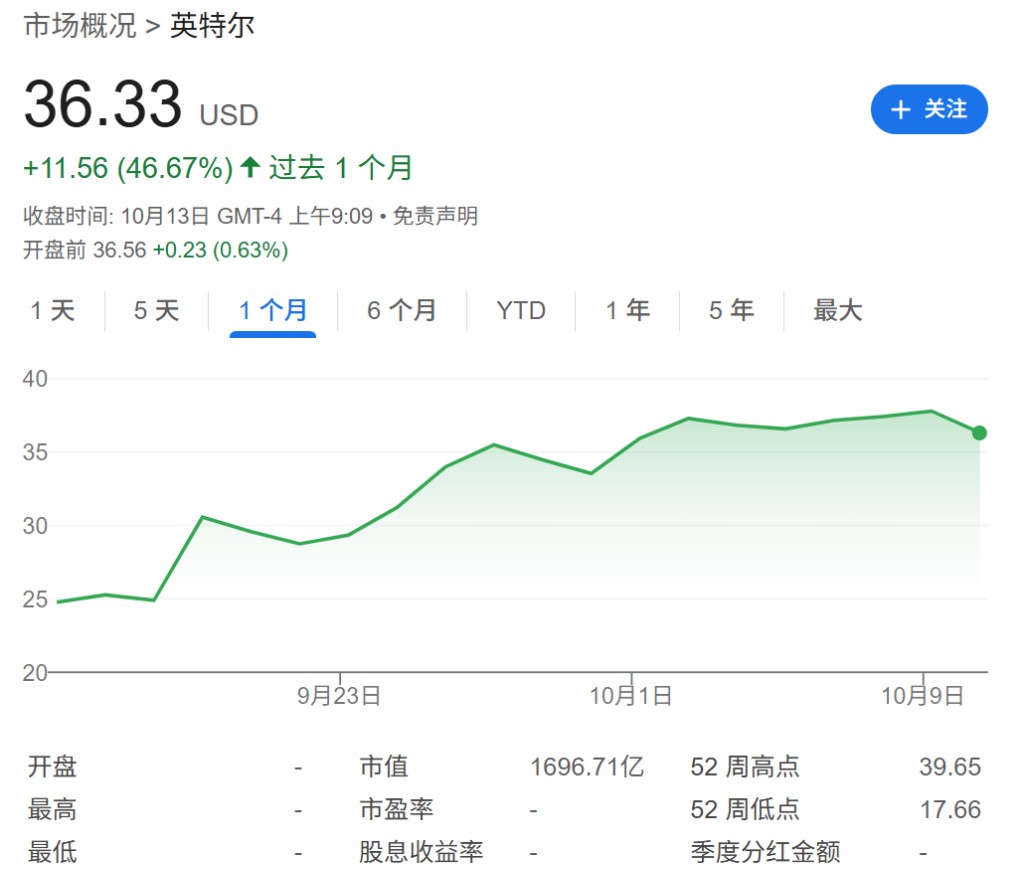

英特爾斥資 320 億美元在亞利桑那州建設的新工廠已投產,試圖用 18A 工藝重新奪回先進製造領域的領導地位。該豪賭成敗將在未來 6-8 個月內由蘋果、英偉達、高通等關鍵客户的測試結果決定。英特爾股價在一個月內上漲超過 46%。

英特爾斥資 320 億美元在亞利桑那州建設的新芯片工廠已開始大規模生產,以重新奪回先進製造領域的領導地位。

據媒體 13 日報道,英特爾代工部門負責人 Kevin O'Buckley 表示,18A 是"目前地球上最先進的半導體生產技術",但他承認公司仍需要"贏得客户信任"。分析師 Ben Bajarin 警告稱:

"到了某個時刻,他們必須決定是否能夠做到。"

這一豪賭將在未來 6-8 個月內見分曉,蘋果、英偉達和高通等關鍵客户的測試結果將決定這家美國芯片巨頭的命運。如果 18A 工藝未能打動客户,英特爾在美國本土芯片製造領域的數十億美元投資可能功虧一簣。該公司代工部門每年虧損超過 100 億美元,同時揹負 200 億美元淨債務。

美國政府已介入支持,將原計劃的補貼轉為股權投資,獲得英特爾 10% 股份。隨後英偉達和軟銀的投資進一步提振信心,英特爾股價在一個月內上漲超過 46%。

鉅額投資面臨嚴峻考驗

英特爾在亞利桑那州錢德勒市建設的 700 英畝芯片工廠耗資將超過該公司 2024 年收入的一半。摩根士丹利分析師表示,"很難為一個每年虧損超過 100 億美元的代工業務賦予太多價值"。

位於該園區的 Fab 52 工廠已投產,未完工的 Fab 62 工廠仍在建設中。Fab 52 所需混凝土用量是迪拜哈利法塔的兩倍,現已安裝來自 ASML 的極紫外光刻設備,每台價值數億美元。

蘋果、英偉達和高通等昔日客户將在未來 6-8 個月內測試英特爾的 18A 芯片,然後決定是否重新合作。這些測試結果對英特爾至關重要,因為該公司需要證明其製造工藝能夠與台積電競爭。分析師表示:

"如果芯片性能良好,這將是開始認真對待英特爾代工業務的積極信號。"

英特爾工程師稱,早期的"良品率"問題已得到解決,公司即將推出兩款新芯片——用於個人電腦的 Panther Lake 和用於服務器的 Clearwater Forest。

“大到不能倒” 的轉變

面對英特爾的困境,美國政府將原計劃的補貼轉換為股權投資,獲得該公司 10% 股份。TechInsights 的 Dan Hutcheson 評論稱:

"英特爾從'太大而無法拯救'變成了'大到不能倒'。"

政府介入後,英偉達和軟銀相繼宣佈投資,推動英特爾股價在一個月內暴漲超過 50%。分析師認為,特朗普政府對大型科技公司支持國內製造業的壓力也可能推動更多客户轉向英特爾。

英特爾必須證明 18A 工藝能夠大規模量產,以獲得其計劃於 2028 年推出的 14A 工藝的預訂單。如果無法吸引足夠客户,英特爾已警告可能放棄這一技術路線。

該公司代工部門負責人承認,儘管擁有先進技術,但"仍需要為客户建立信任"。在台積電長期主導高端芯片代工市場的背景下,英特爾面臨的挑戰不僅是技術層面,更在於説服客户相信其執行能力。