Intel's brand new 18A process AI PC chip makes its debut, with full production at its U.S. manufacturing plant

18A 製程是英特爾首個在美國開發製造的 2 納米級節點,相較前代實現 15% 的性能功耗比提升和 30% 的芯片密度改進。Panther Lake 架構的英特爾酷睿 Ultra 第三代處理器預計今年底開始出貨。英特爾在亞利桑那州的 Fab 52 工廠準備今年晚些時候大規模生產 18A 製程芯片。

除了吸引外部投資,努力擺脱困境的英特爾還在推動在美國本土生產其最先進製程的產品。

美東時間 10 月 9 日週四,英特爾首次透露 18A 製程工藝的首款產品——代號 Panther Lake 的新一代 AI PC 處理器架構細節。這是英特爾在美國製造最先進半導體節點方面取得的關鍵突破。

Panther Lake 架構的英特爾酷睿 Ultra 第三代系列處理器預計今年底開始出貨,明年初、即 2026 年 1 月實現廣泛市場供應。與此同時,英特爾披露,位於美國亞利桑那州錢德勒市的 Fab 52 工廠已全面投產,準備今年晚些時候大規模生產 18A 製程芯片。

英特爾還預覽了基於 18A 製程的首款服務器處理器至強 6+,計劃 2026 年上半年推出。18A 製程是英特爾首個在美國開發和製造的 2 納米級節點,相較前代產品實現 15% 的性能功耗比提升和 30% 的芯片密度改進。

自今年 3 月上任以來,英特爾 CEO 陳立武面臨巨大的公司轉型壓力。截至本週三收盤,英特爾股價今年內已累漲近 87%,公司仍在努力追趕人工智能(AI)革新帶來的前沿芯片需求。週四英特爾有望小幅收漲,三連漲,刷新一年半來收盤高位。

Panther Lake 架構:多芯片設計提升 AI 性能

英特爾酷睿 Ultra 第三代處理器採用可擴展的多芯片架構,為合作伙伴在不同外形規格、細分市場和價格點提供前所未有的靈活性。

該處理器配備最多 16 個性能核心和效率核心,CPU 性能較前代提升超過 50%。集成的英特爾 Arc GPU 配備最多 12 個 Xe 核心,圖形性能同樣提升超過 50%。芯片採用平衡的 XPU 設計,AI 加速能力達到 180 Platform TOPS。

除 PC 應用外,Panther Lake 還將擴展至邊緣應用,包括機器人領域。英特爾推出新的機器人 AI 軟件套件和參考板,幫助客户利用 Panther Lake 開發控制和 AI 感知功能。

亞利桑那州工廠投產 強化美國製造

Fab 52 是英特爾在亞利桑那州錢德勒 Ocotillo 園區的第五座大型晶圓廠,現已全面投產並準備使用 18A 製程進行大規模生產。該工廠生產美國境內最先進的邏輯芯片,是英特爾 1000 億美元在美擴張投資的重要組成部分。

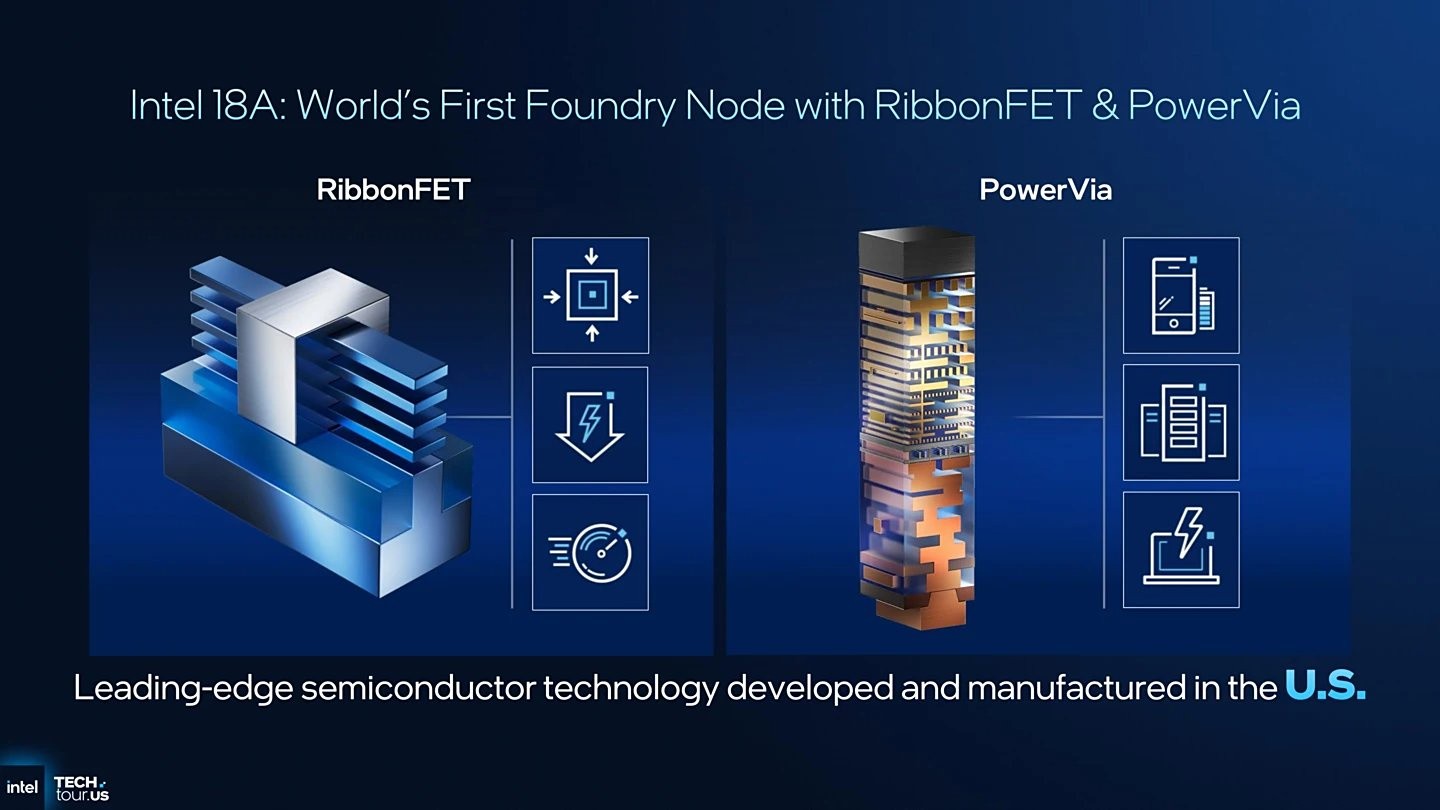

18A 製程融合了 RibbonFET 全環繞柵極晶體管技術和 PowerVia 背面供電系統兩大創新。RibbonFET 是英特爾十多年來首個全新晶體管架構,實現更好的縮放和更高效的開關性能。PowerVia 則是突破性的背面供電系統,增強功率流和信號傳輸。

英特爾表示,18A 製程將成為未來至少三代客户端和服務器產品的基礎。憑藉俄勒岡州的先進研發和生產、亞利桑那州的大規模製造以及新墨西哥州的封裝業務,英特爾為支持特朗普政府的所謂 “美國優先” 事項和英特爾代工服務客户提供戰略產能。

服務器芯片佈局:至強 6+ 瞄準數據中心

代號 Clearwater Forest 的至強 6+ 處理器配備最多 288 個效率核心,每週期指令數較前代提升 17%,在密度、吞吐量和功耗效率方面實現顯著提升。

該處理器專為超大規模數據中心、雲服務提供商和電信運營商定製,幫助組織擴展工作負載、降低能源成本並支持更智能的服務。至強 6+ 計劃 2026 年上半年推出,與 Panther Lake 一同在 Fab 52 生產。

英特爾 CEO 陳立武表示:"我們正進入一個激動人心的計算新時代,半導體技術的巨大飛躍將塑造未來數十年。美國一直是英特爾最先進研發、產品設計和製造的家園,我們為在擴展國內業務和將新創新推向市場時延續這一傳統而感到自豪。"